Powering a diverse range of modern portable electronic devices and securing safe operation of big data centers and networks for the ‘internet of things’ are becoming an urgent need that influences our daily lives. However, the ever-increasing demand for energy storage devices with improved performance and stability in all the above-mentioned sectors as well as in transportation (electric vehicles), grid storage (large energy storage and power levelling), electronics in space applications (satellites, new missions), and implanted medical devices (e.g., implantable cardioverter defibrillators, pacemakers) is motivating the scientific community to develop new chemistries, compositions, and morphologies of electrode materials.

Currently, rechargeable lithium-ion batteries (LIBs)—the most widely used electrochemical energy storage system of today—are used only in a limited number of applications because of power densities and fire safety issues. For example, electric vehicles will benefit from energy storage devices with high charging/discharging rate capabilities (power density) for acceleration or for energy management (recharging during vehicle braking). These limitations have stimulated intensive research towards the hybridization of LIBs with energy storage systems having higher power densities. Traditional capacitors possess power densities that are high enough for such applications; however, their energy density is too low. We thus propose a cutting-edge supercapacitor technology based on new material that possesses both high power and high energy density. We intend to take this important field beyond its state-of-the-art via the exploitation of the previously unexplored properties of the material, thus imparting top-rated performance to the respective energy storage devices.

Supercapacitors

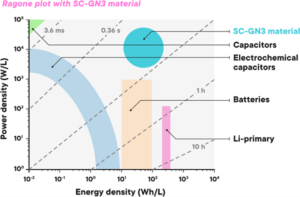

Supercapacitors (SCs) are energy storage devices with remarkable qualities including fast charging/discharging (i.e., high power) and extra-long life-cycles (i.e., they can be charged and discharged for hundreds of thousands of cycles). On the other hand, to match the energy density (i.e., the ability to store charge/energy) of the marketed batteries remains a challenging task. Commercial SCs have cell-level specific energies (and energy densities) of 10 Wh/kg (58 Wh/L). For comparison, lead-acid batteries offer 20–35 Wh/kg (40-80 Wh/L), whereas state-of-the-art Li-ion batteries achieve ̴250 Wh/kg ( ̴400 Wh/L) (Figure 1).

We developed a nitrogen super-doped graphene electrode material (SC-GN3 [LINK to PDF of the material]) with an unprecedented density of 2.8 g/cm3. The ultrahigh mass density of SC-GN3, combined with its polar nitrogen moieties and vacancies enabling fast charge transport, allow reaching an energy density of 200 Wh/L at a power density of 2.6 kW/L. Such a performance, obtained from a symmetric SC full cell, corresponds to an improvement by 74 % and 190 % in energy and power density, respectively, compared to the previous record reported in the scientific literature (link) . Therefore, the utilization of SC-GN3 in SCs holds great potential toward novel energy storage devices having the energy density of up to 200 Wh/L, approaching that of some rechargeable batteries, while enabling fast charging/discharging and long life-cycle stability because SC-GN3 displays 100% retention of capacitance after 10,000 cycles at 20 A/g.

Figure 1 The Ragone plot shows that SC-GN3 supercapacitor material lays the ground for achieving energy densities similar to batteries, while keeping the power performance of supercapacitors.

Supercapacitor devices

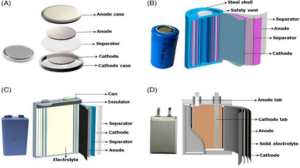

Two main construction types of SCs dominate in the market today. The pouch (stacked) type brings maximum energy density and the wound (cylindrical) type fits better high manufacturing volumes at lower cost but also at slightly lower energy density with respect to the pouch type (Figure 2).

Figure 2. Construction geometries used for energy storage devices (batteries, capacitors and supercapacitors), a) coin cell, b) wound (cylinder), c) prismatic and d) pouch cell (source: Info Mat 1(1):6–32, 2019).

We propose here a new electrode material that enables energy density far beyond the competition in the SC field, even approaching that of some rechargeable batteries, along with extended cycle-life and high-power density exceeding the state-of-the-art of this field. The added value of the SC-GN3 material also lies in its composition, which is based only on carbon (in the form of black powder).

Figure 3. Photograph of as prepared SC-GN3 material and electrodes.